AISI H13 Tool Steel/DIN 1.2344/JIS SKD61

- Shizhang Steel

- China

- 7-35days

- 500 Tons/Month

AISI H13 tool steel / 1.2344 is characterized by its high hardness, wear resistance, toughness, and corrosion resistance. AISI H13 steel / 1.2344 can withstand high temperature and high pressure loads. AISI H13 steel / 1.2344 can reduce the tooling wear and improve production efficiency.

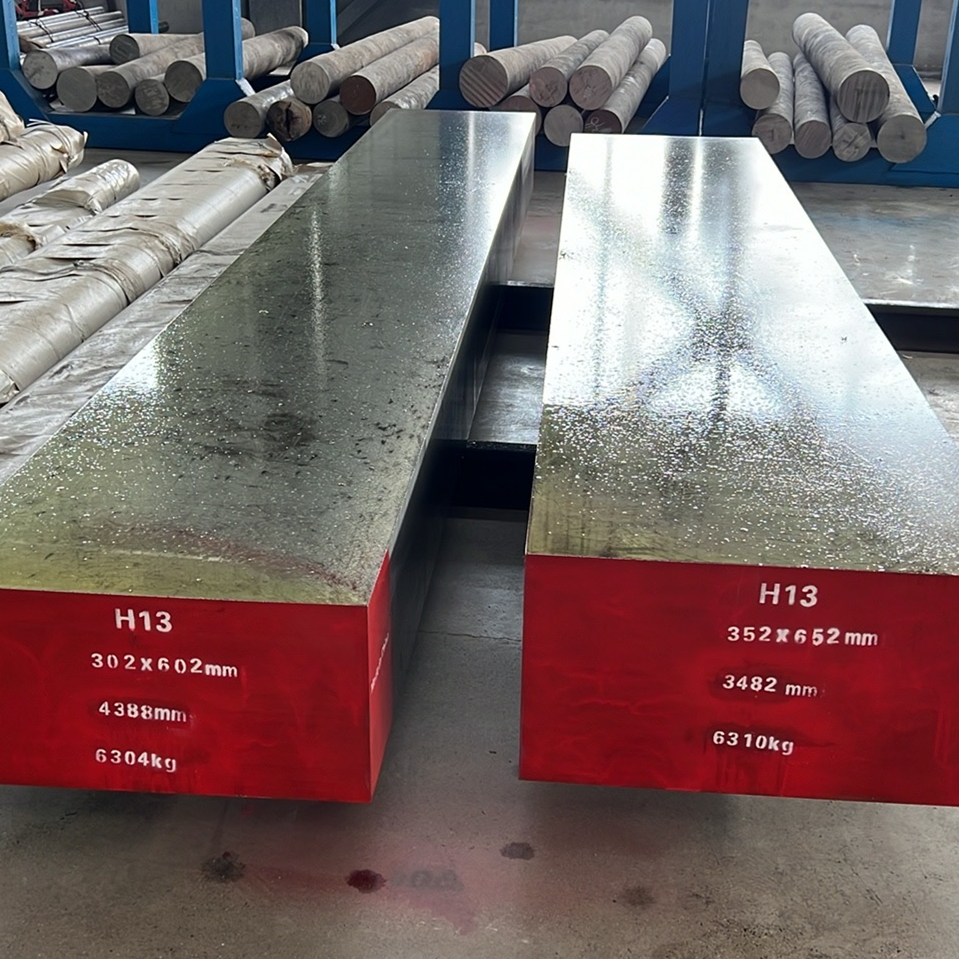

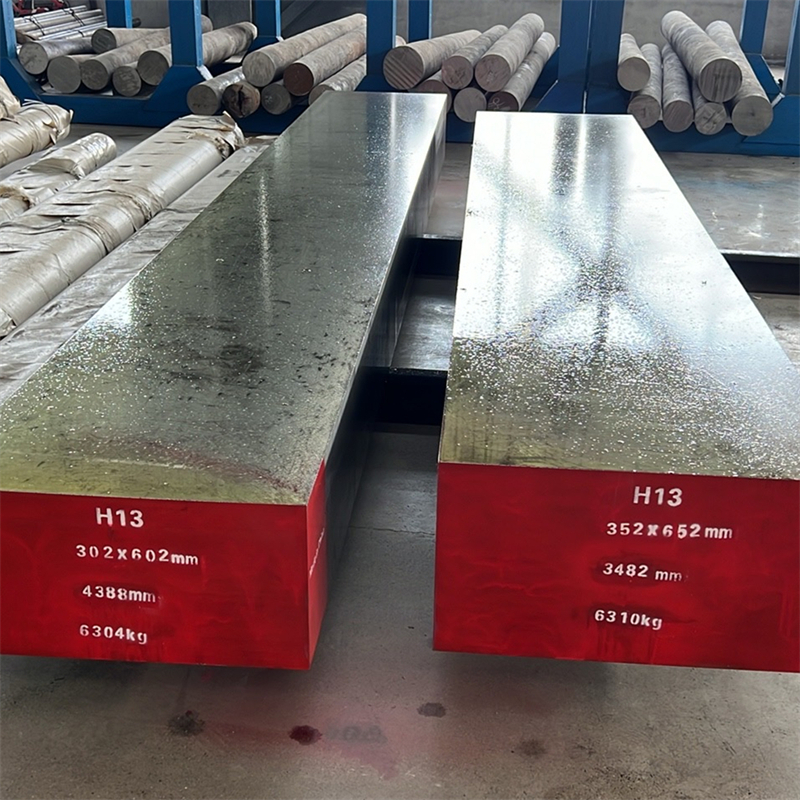

Product Name: HOT WORK TOOL STEEL---AISI H13 / 1.2344

Similar steel grades:

AISI | H13 |

DIN | 1.2344 |

JIS | SKD 61 |

ASSAB | 8407 |

GB/T1299-2000 | 4Cr5MoSiV1 |

ISO | X40CrMoV5-1 |

Chemistry (in %)

C | Si | Mn | Cr | Mo | V | P | S |

0.32-0.45 | 0.80-1.20 | 0.20-0.50 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 | 0.03max | 0.03max |

Principal Feature:

AISI H13 / 1.2344 Hot work tool steel air hardening, with good toughness, resistance. It resists softening to 550℃ and has good resistance to heat checking. Will nitride with a case hardness over 1000 V.P.N. Generally supplied annealed to HB 230.

Typical Application:

1.2344 steel is used for hot punches and dies for blanking, bending, forging, and forging; for hot extrusion dies for aluminum; and for cores, ejectors, inserts, and nozzles for aluminum, tin, and lead die casting.

Heat Treatment:

Forge: at 900℃-1100℃ Cool slowly and anneal immediately

Annealing: at 850℃-870℃ Cool slowly in furnace

Stress Relieving: at to 600℃-650℃ Cool in still air

Hardening: Preheat at 650℃-850℃ raise to 1020℃-1050℃ Cool in air, oil or into salt bath held at 500℃-550℃ and then air cool.

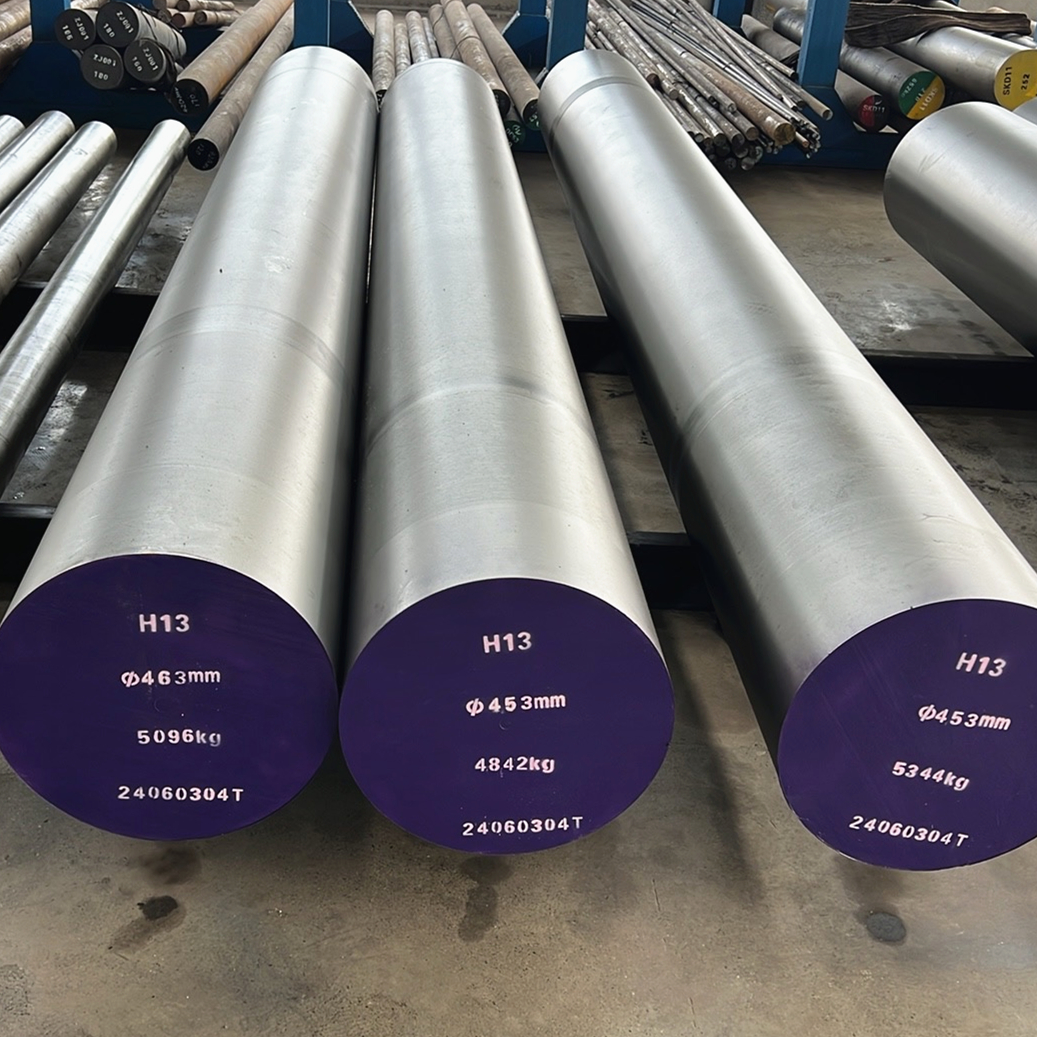

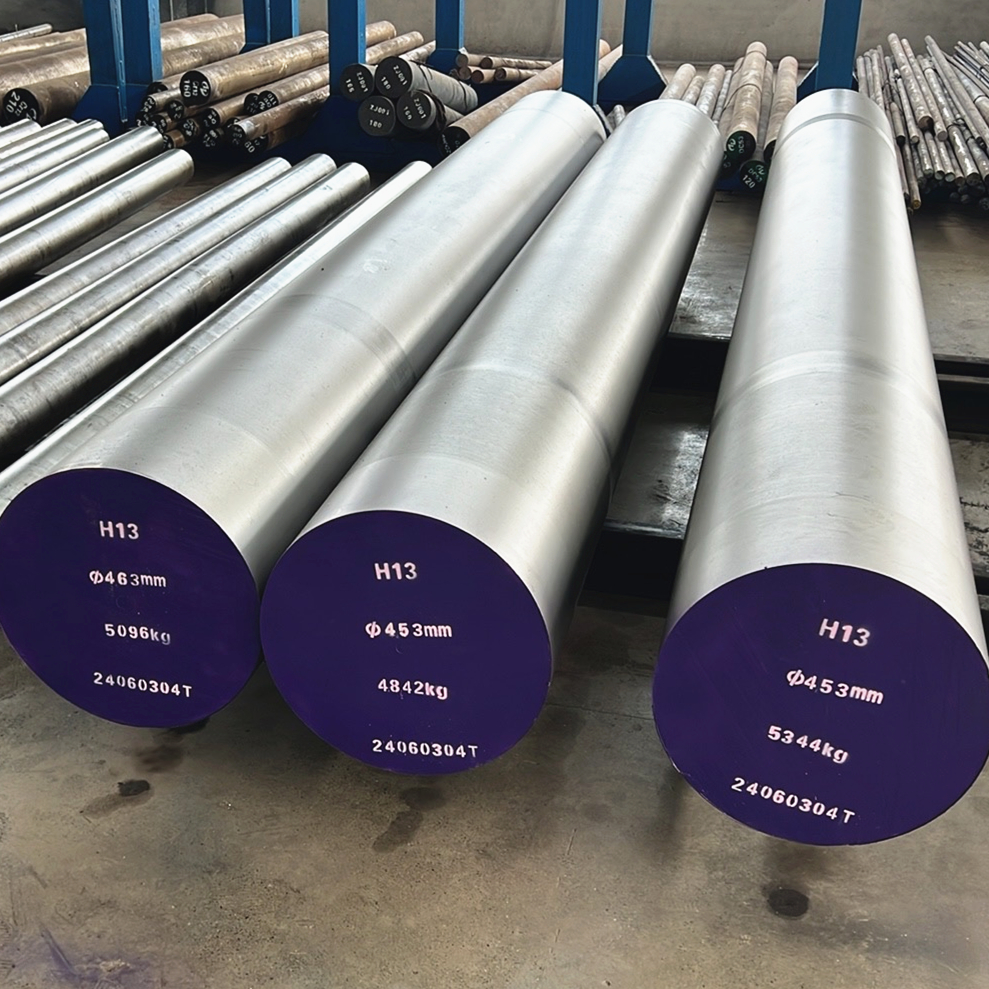

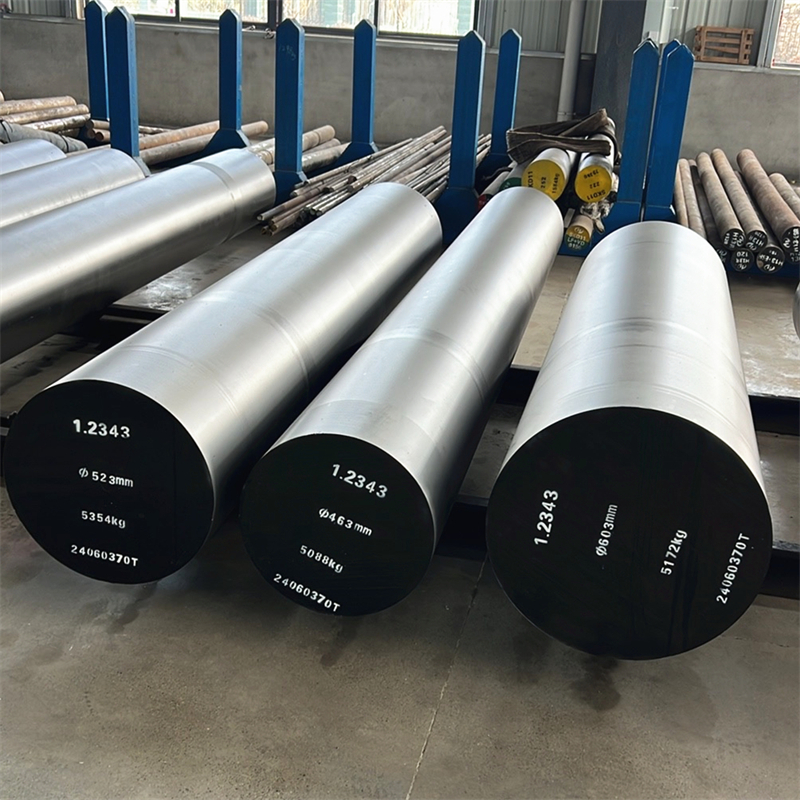

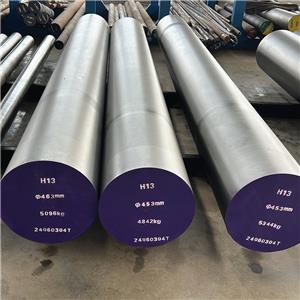

Bars | Turned | Dia20-800mm |

Black | Dia 20-800mm | |

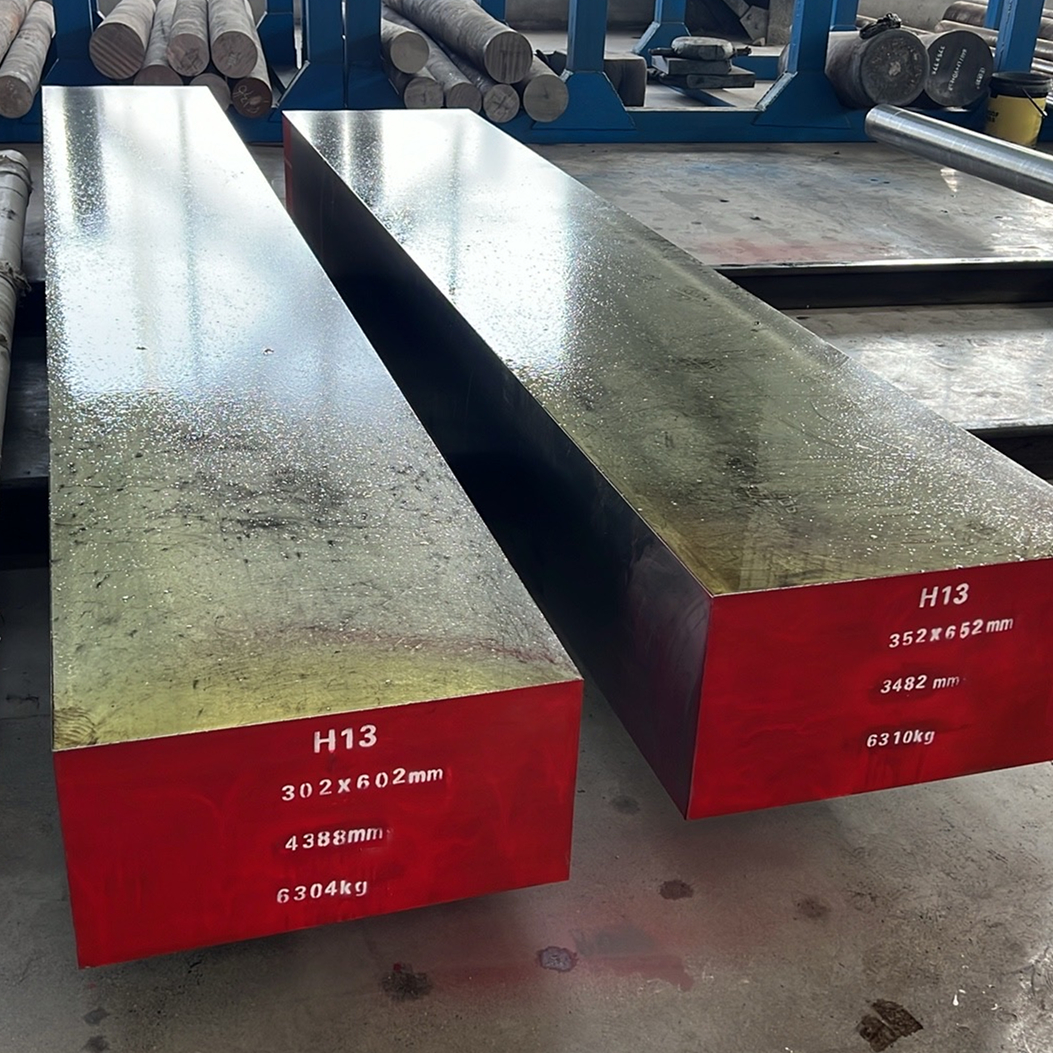

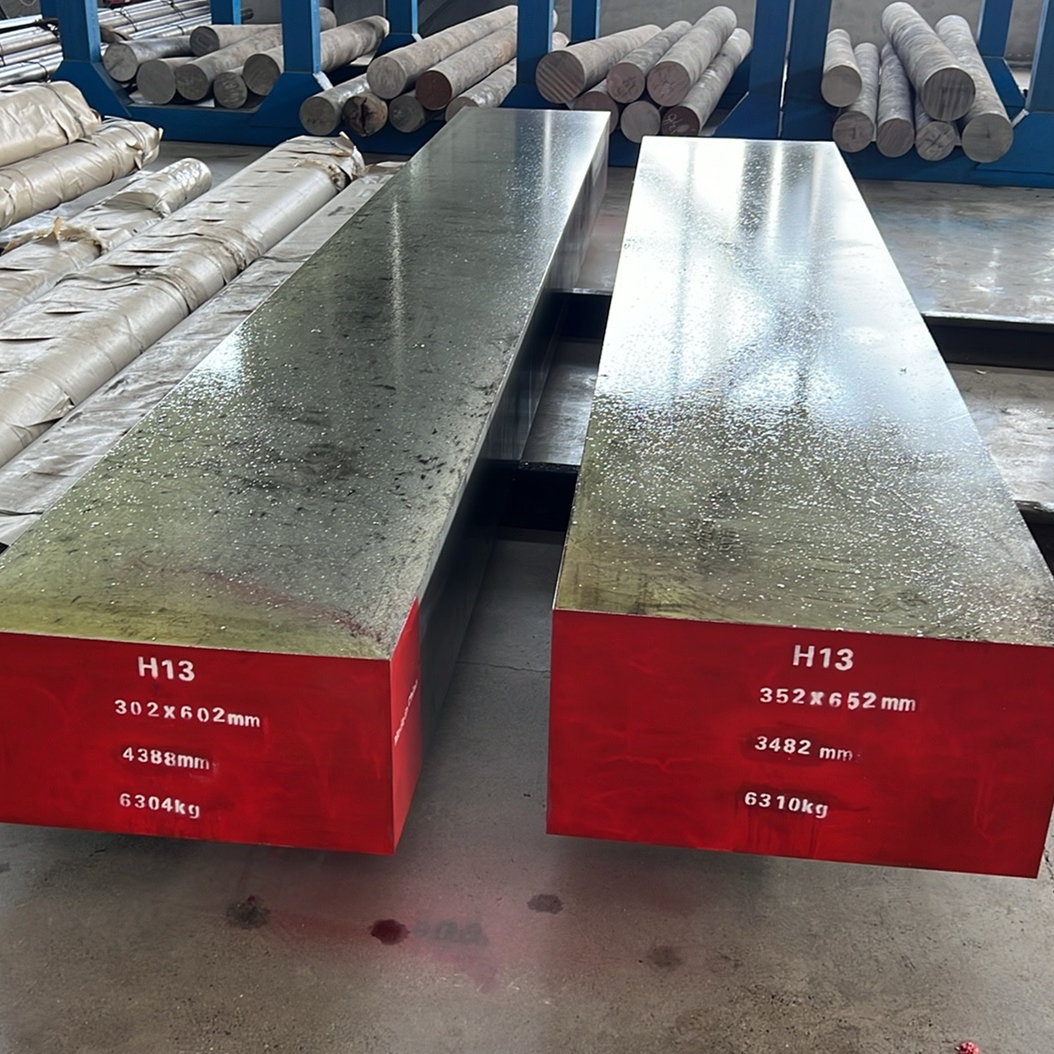

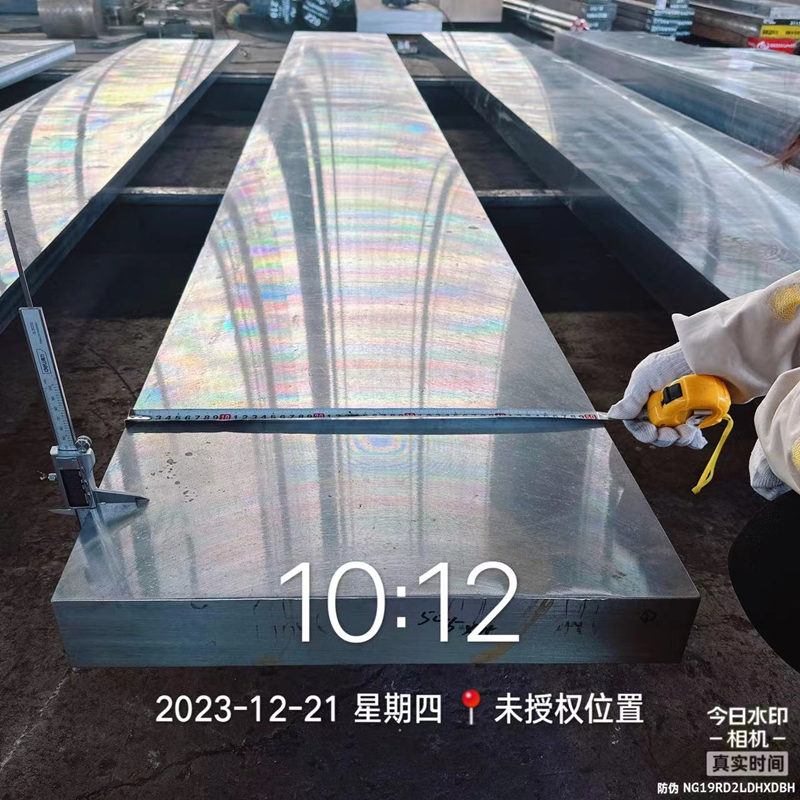

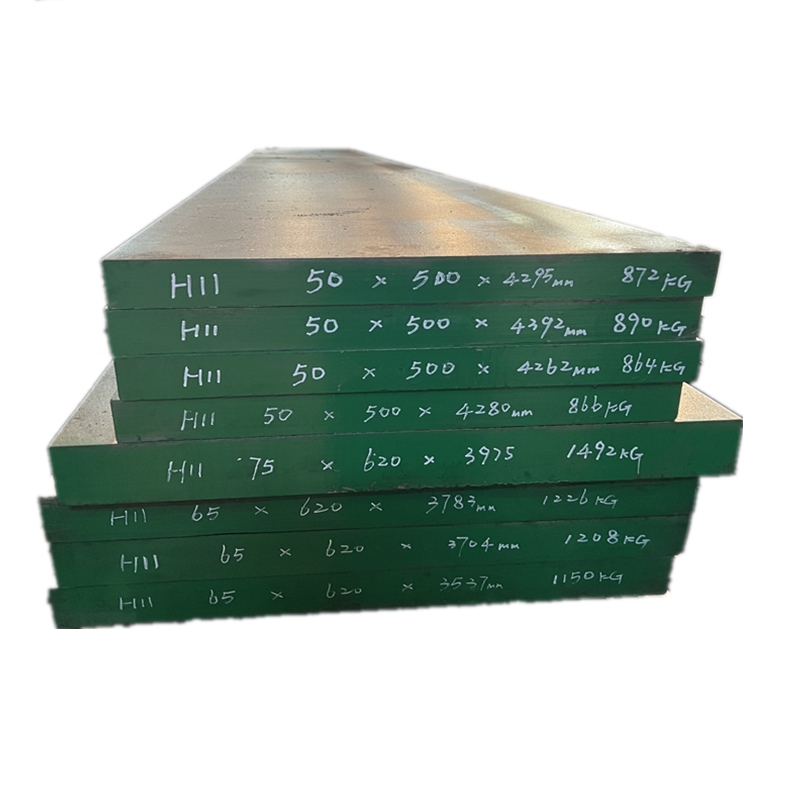

Flats | Milled | T: 8-400 W: 210-610mm |

Black | T: 8-400 W: 210-610mm |

AISI H13 tool steel / 1.2344 steel