5CrW2SiV Alloy Tool Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

1. Wear Resistance:

- Vanadium carbides (VC) significantly improve abrasion resistance

- Suitable for processing hard particulate materials

2. Thermal Stability:

- Short-term service temperature up to 450℃

- Outperforms conventional CrWMn steels

3. Processability:

- Forging temperature range: 1100-850℃

- Annealed hardness: ≤229HB

Product Name: ALLOY STEEL---5CrW2SiV

Similar steel grades:

U.S.A | S1/T41901 |

German | 1.2542 |

Japan | - |

Austria | - |

Sweden | 2710 |

China | 5CrW2SiV |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | w | Ni | Cu |

GB/T1299-2000 | 0.45–0.55 | 0.5–0.8 | ≤0.4 | ≤0.03 | ≤0.03 | 1–1.3 | 2–2.5 | ≤0.25 | ≤0.3 |

Principal Feature:

5CrW2SiV is an enhanced alloy tool steel with vanadium (V) modification, offering:

- Optimized carbide distribution (V-refined grain structure)

- Enhanced wear resistance and red hardness

- Excellent strength-toughness balance

- Superior tempering resistance.

Typical Application:

- Precision blanking dies (especially for <3mm thin sheets)

- Cold forging dies (bolt/nut forming)

- Plastic molds (reinforced fiber processing)

- Cutting tools (slitting knives, trimming blades).

Heat Treatment:

A[Spheroidize Annealing 790℃×4h→720℃×6h] --> B[Quenching 980-1020℃ oil cooling]

B --> C[Cryogenic Treatment -80℃×2h]

C --> D[Tempering 180-220℃×2h],.

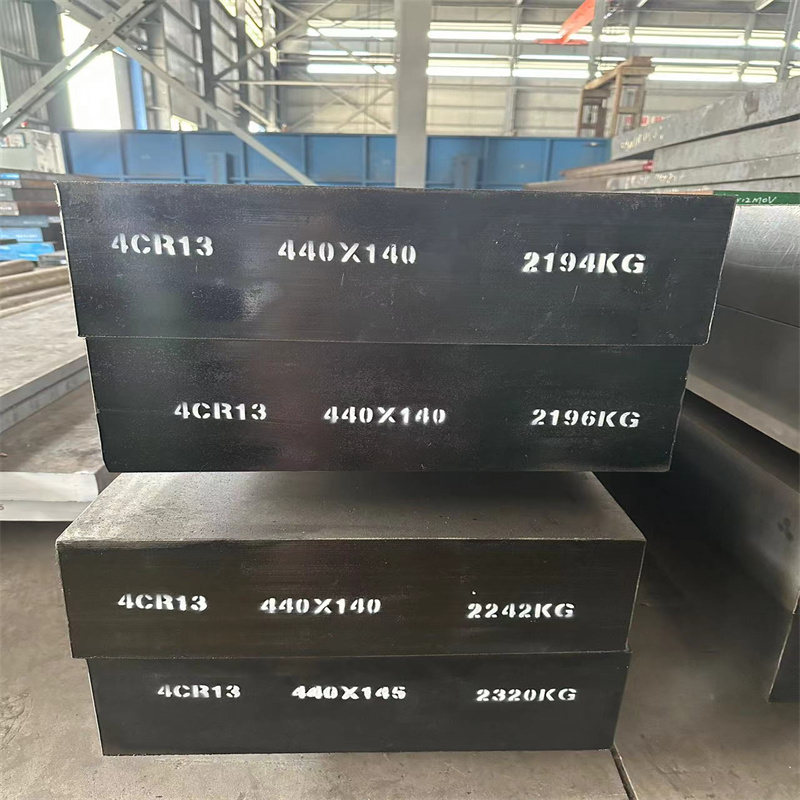

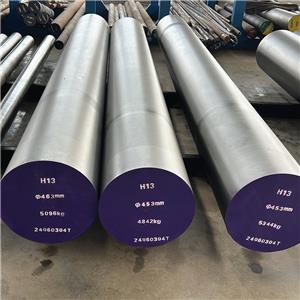

Size available:

Bars | Turned | Dia 90-505mm |

Black | Dia 60-550mm | |

Flats | Milled | T: 70-320 W: 90-1000mm |

Black | T: 50-320 W: 90-1000mm |

We can provide professional steel as per your detail requirement!