Alloy Steel 60Si2Mn

This is a strong, high-quality spring steel with good hardenability, hot work performance, and comprehensive mechanical properties, often used for large, high-stress springs in automobiles, tractors, and industrial equipment.

Product Name: ALLOY STEEL---60Si2Mn(Alloy Steel )

Similar Steel Grades:

China | GB/T | 60Si2Mn |

Germany | EN/DIN | DIN 60Si7/1.0909 |

Russia | GOST | Near 60C2M |

U.S.A | AISI/SAE | Near 9260 |

Japan | JIS | SUP6/SUP7 |

France | AFNOR | 60S7 |

Chemical Composition(%) :

C | Si | Mn | P | S | Cr | Ni |

0.56-0.64 | 1.50-2.00 | 0.60-0.90 | 0.035max | 0.035max | 0.35max | 0.35max |

Principal Feature:

This is a strong, high-quality spring steel with good hardenability, hot work performance, and comprehensive mechanical properties, often used for large, high-stress springs in automobiles, tractors, and industrial equipment.

Typical Application:

Springs: coil springs, leaf springs, tension/compression springs, torsion springs (used in automotive suspension and machinery).

Elastic components: spring steel strips, spring plates, rods (used in automotive, valves, tools, measuring instruments).

Other uses: high-fatigue structural elements (elastic blades, latching mechanisms).

Mechanical properties:

Tensile strength : ≈ 1200-1300 MPa. High-strength after quenching & tempering

Yield strength : ≥ 1100-1176 MPa. Depends on tempering temperature.

Elongation : ≥ 5 %. Indicates ductility after heat treatment.

Reduction of Area: ≥ 25%. Measures ductility at fracture.

Hardness(as rolled/hot rolled): ≤ 321 HB. For easier machining and forming.

Hardness(quenched & tempered): Typically 45-52 HRC( varies by tempering). Optimized for elasticity and fatigue.

Heat Treatment:

For spring applications, common processes include:

Normalizing / Annealing

Normalizing: 860–900 °C, air cool (refines grain, relieves stress).

Annealing: 700–720 °C, furnace cool (softens for machining/processing).

Quenching + Tempering (final properties)

Quenching (austenitizing): 800–870 °C (commonly 800–850 °C), hold depending on section size, then oil quench or salt-bath quench.

Tempering: 380–480 °C (commonly 400–450 °C), hold ~1 h, air cool. Produces high elasticity and fatigue strength.

Other advanced processes.

Graded quenching, subcritical tempering, or reverse-transformation quenching are sometimes used in specialized cases to further improve the strength-toughness-fatigue balance.

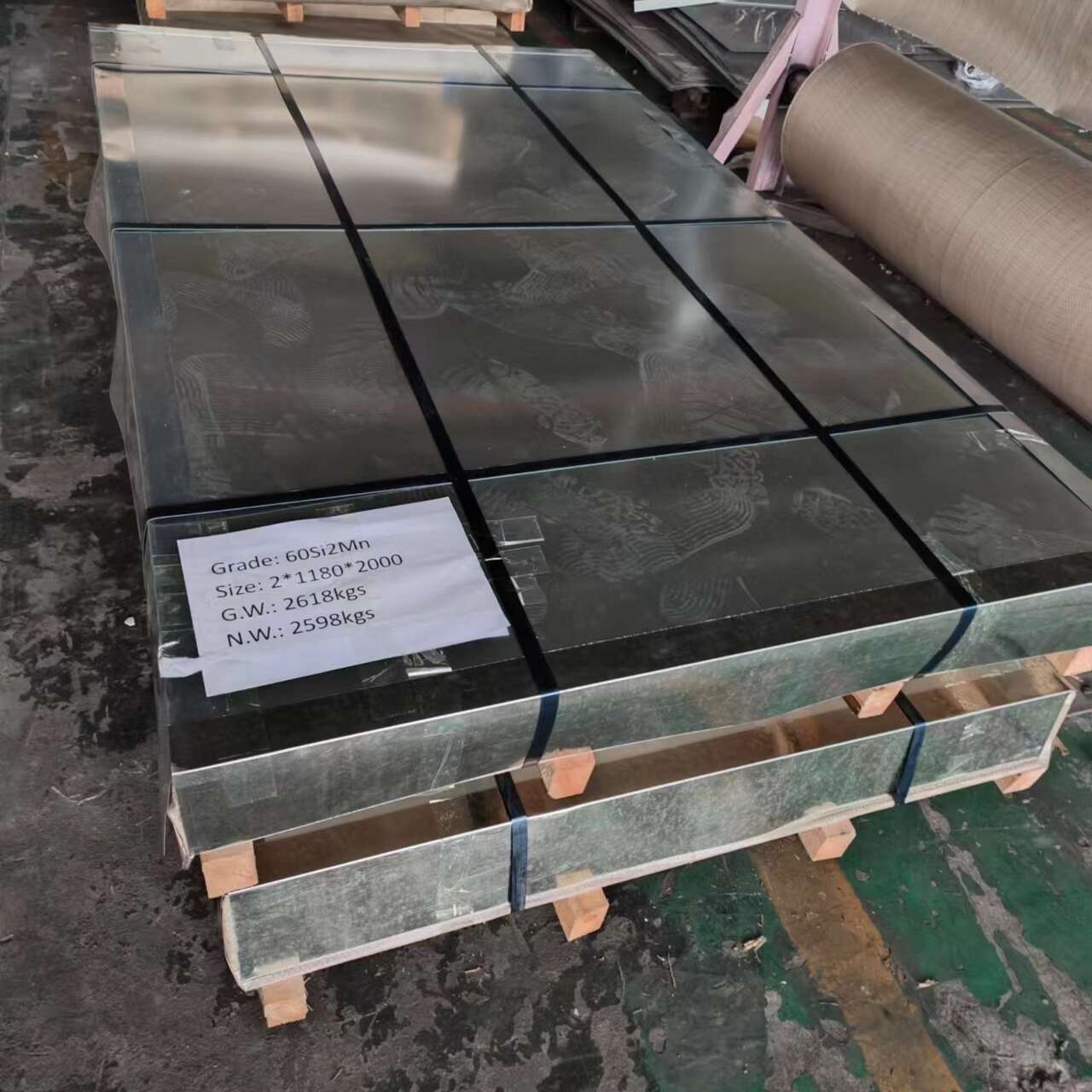

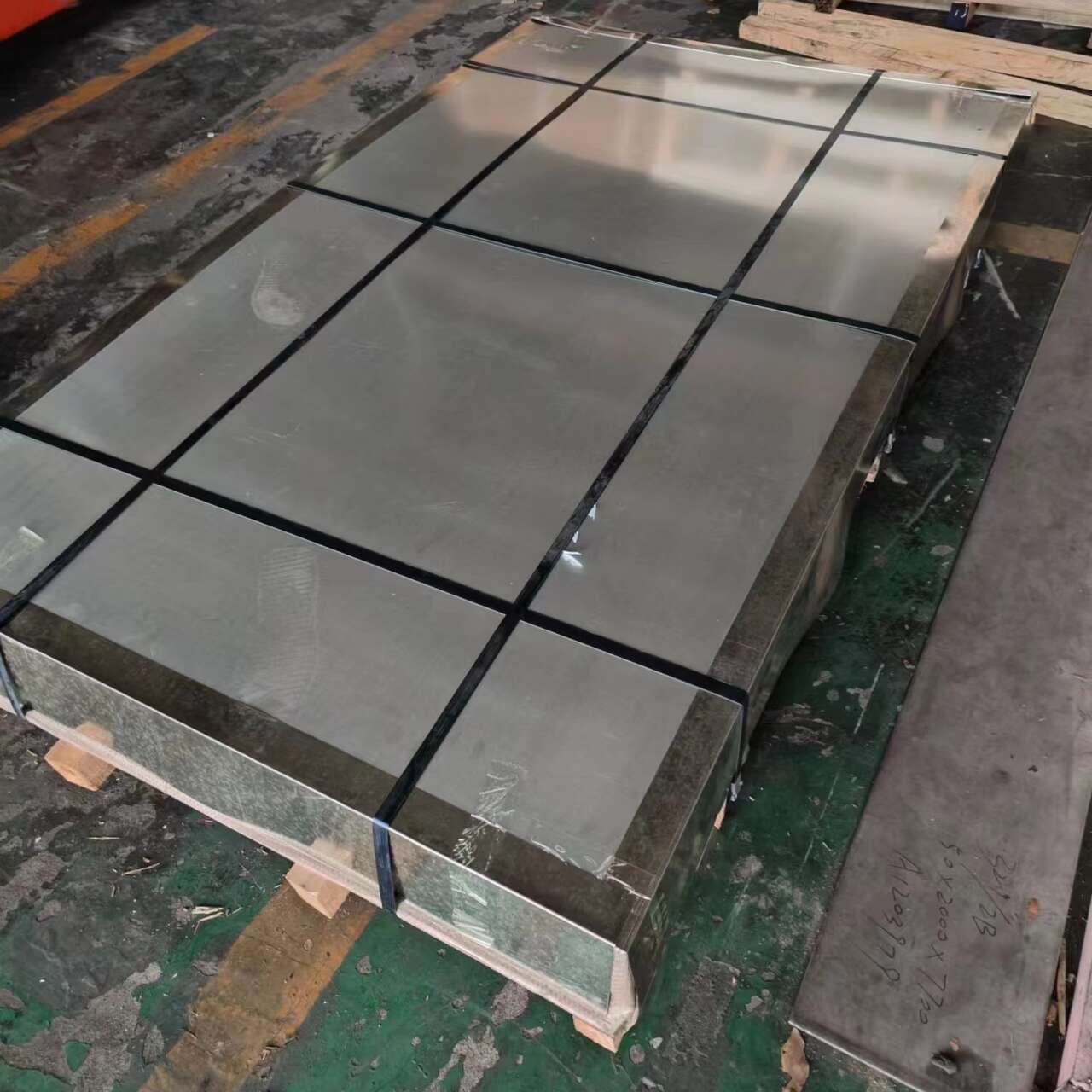

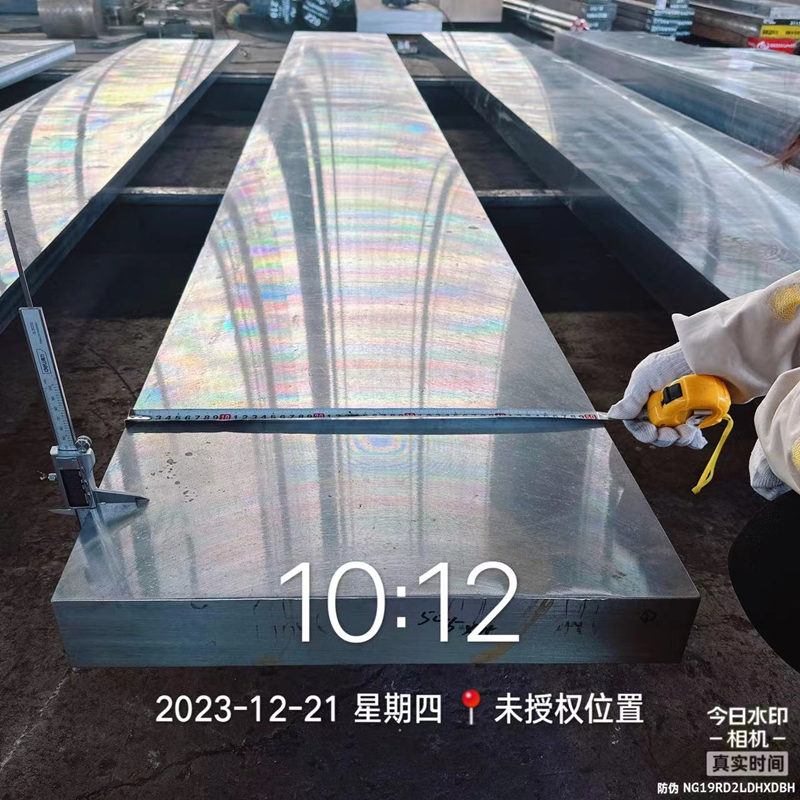

Size available:

Sheets or coils | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |