Alloy Steel 80CrV2

80CrV2 (pronounced "eighty C-R-V-two") is a high-carbon, low-alloy steel known for its excellent combination of toughness, edge stability, and ease of sharpening. It's often described as a superior version of classic high-carbon steels like 1080, with improved hardenability and performance due to its small but effective alloying elements.

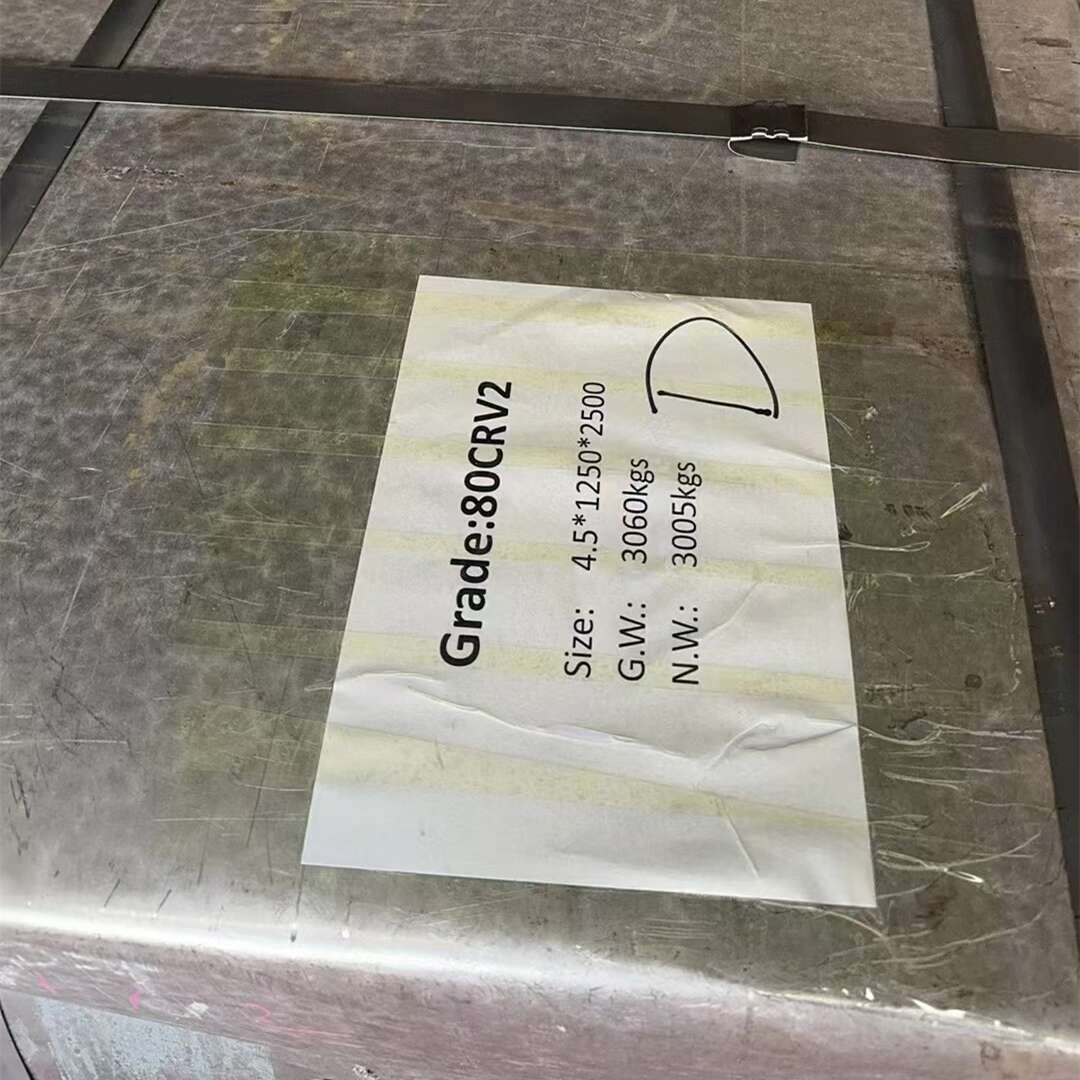

Product Name: ALLOY STEEL---80CrV2(Alloy Steel )

Similar Steel Grades:

China | GB/T | 80CrV2 |

Germany | EN/DIN | 80CrV2/1.2235 |

Russia | ГОСТ | 80ХФА (80KhFA) |

U.S.A | AISI/SAE | Near 1080+V |

France | AFNOR | 80CrV2(Z80CrV2) |

Sweden | SS | 1770 |

Japan | JIS | SK85 /SKS85 |

Chemical Composition(%) :

C | Si | Mn | Cr | V | P | S |

0.75-0.85 | 0.25-0.35 | 0.50-0.70 | 0..40-0.60 | 0.15-0.25 | 0.030max | 0.03max |

Principal Feature:

80CrV2 (pronounced "eighty C-R-V-two") is a high-carbon, low-alloy steel known for its excellent combination of toughness, edge stability, and ease of sharpening. It's often described as a superior version of classic high-carbon steels like 1080, with improved hardenability and performance due to its small but effective alloying elements.

Typical Application:

It's a favorite among custom knifemakers, especially for outdoor, bushcraft, and hunting knives where a resilient edge that can withstand impact and abuse is more critical than extreme wear resistance.

Mechanical properties:

Annealed status

Tensile strength (Rm) : ≈ 750-850 MPa

Yield strength (Rp0.2) : ≈ 450-550 MPa

Elongation (A5) : ≈ 15-20%

Impact toughness: Good

Hardness: ≈ 200 HB (~ 20-22 HRC)

It is convenient for cutting and cold working under this condition.

Heat Treatment:

Forging temperature: 800–1050°C, final forging temperature ≥ 800°C

Quenching: Heating at 830–860°C, oil cooling

Tempering: Tempering at 180–250°C for 1–2 hours to achieve approximately 58–62 HRC; for higher toughness, tempering above 300°C is recommended.

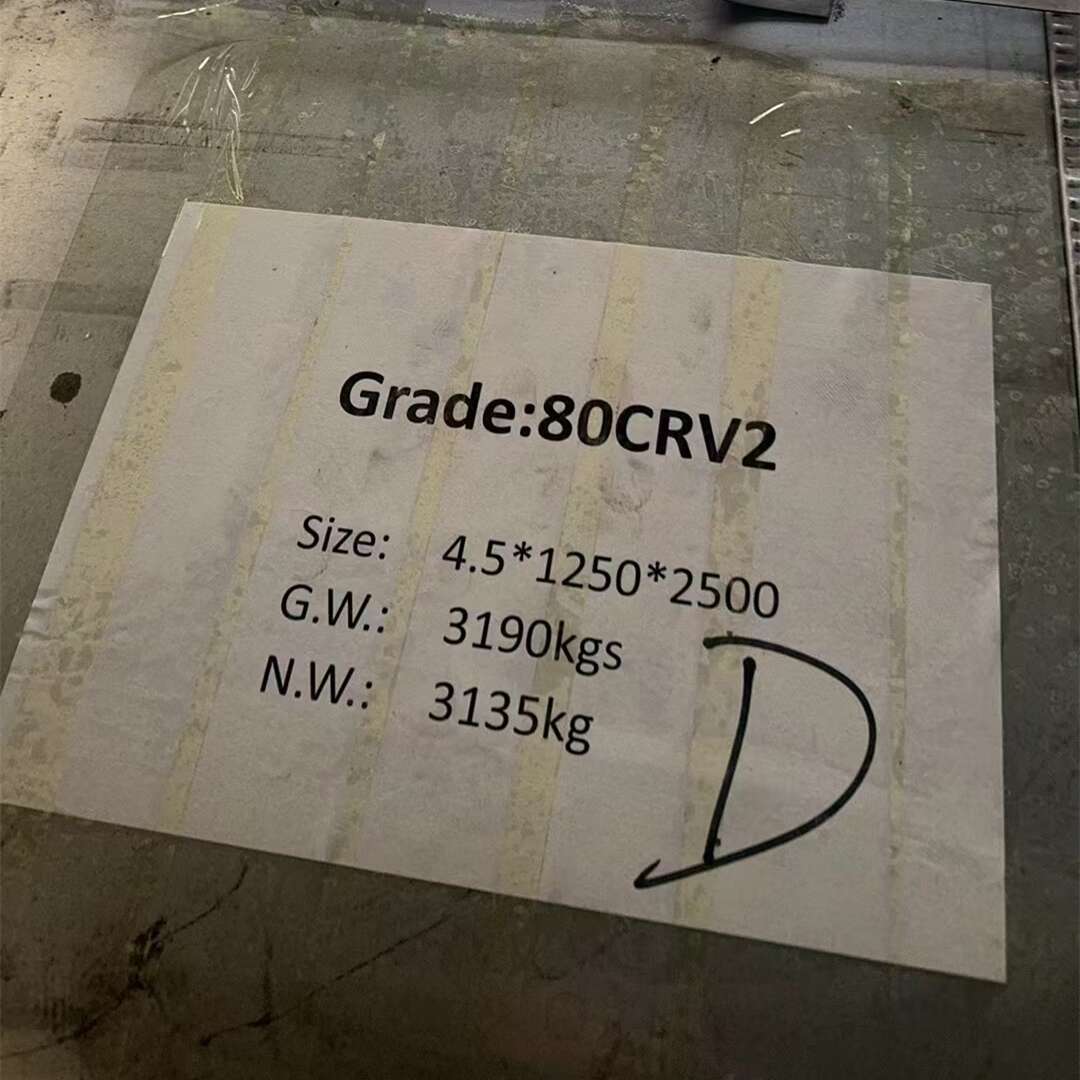

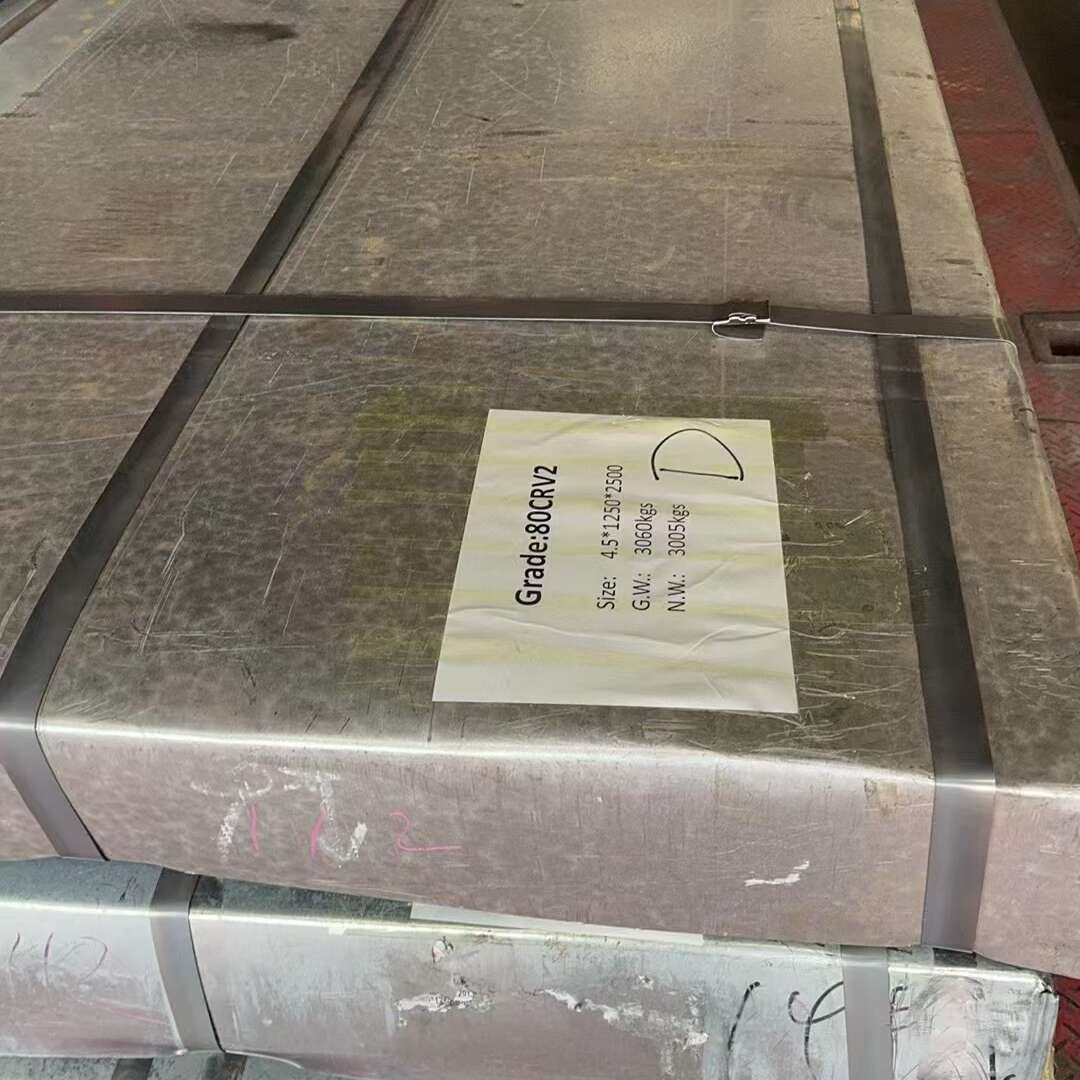

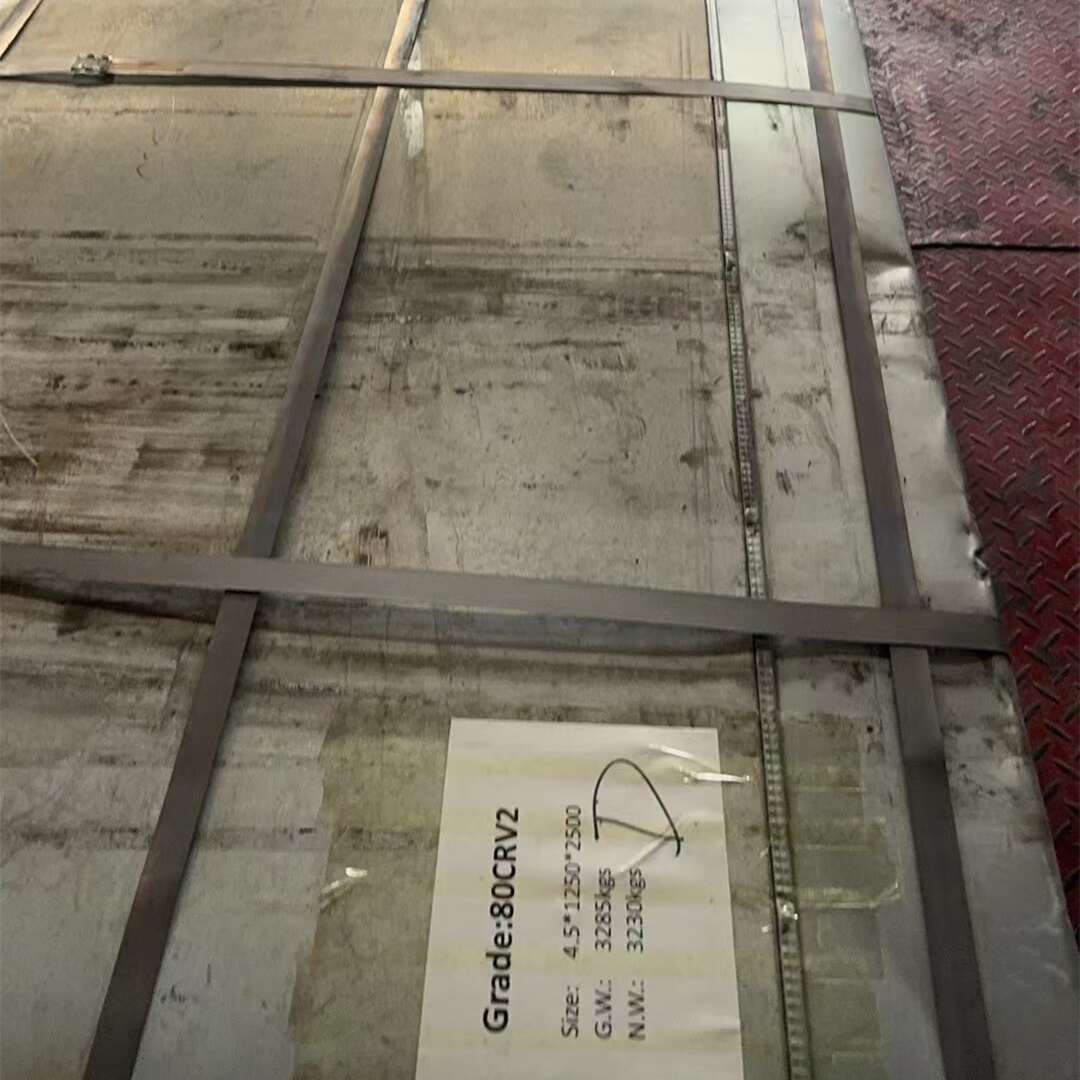

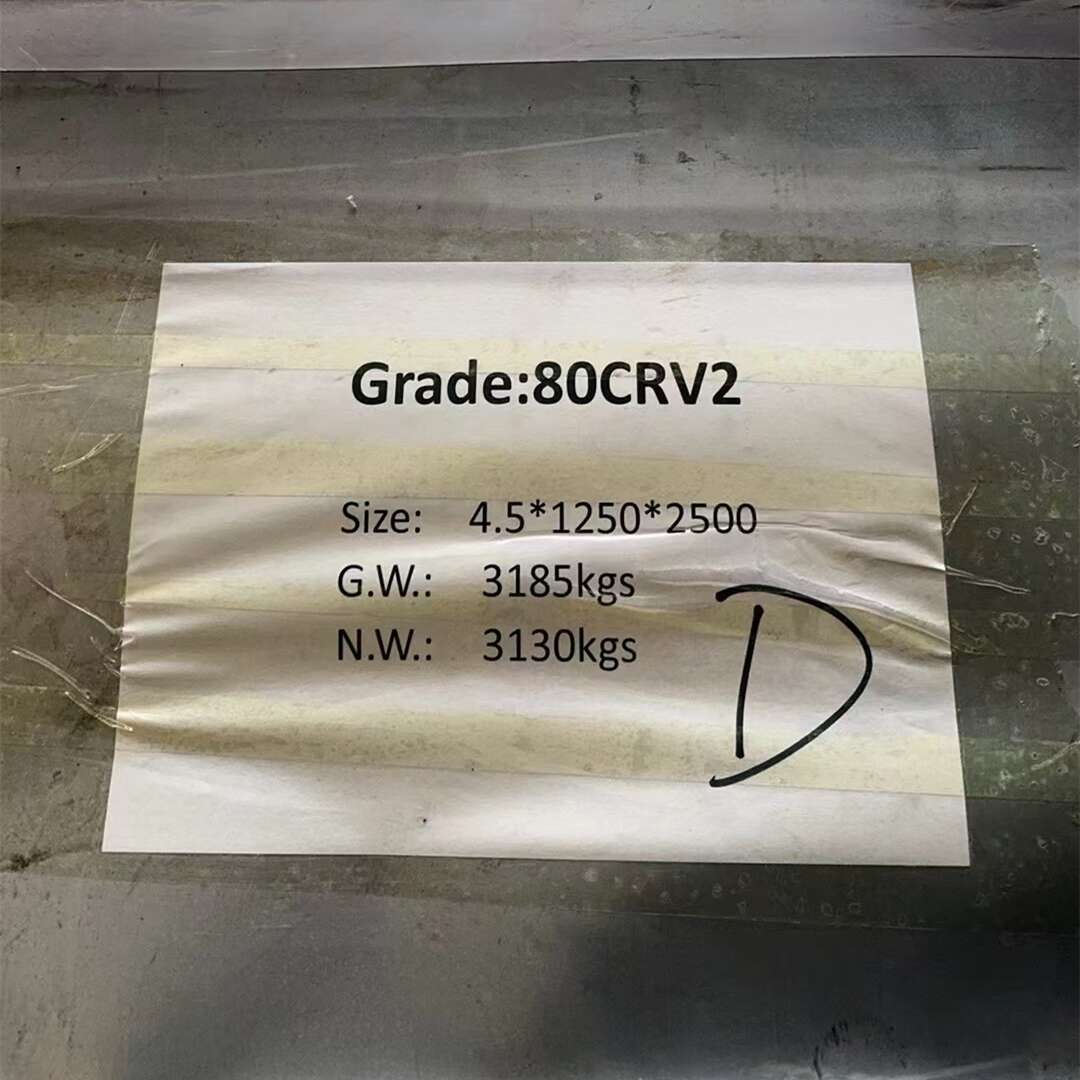

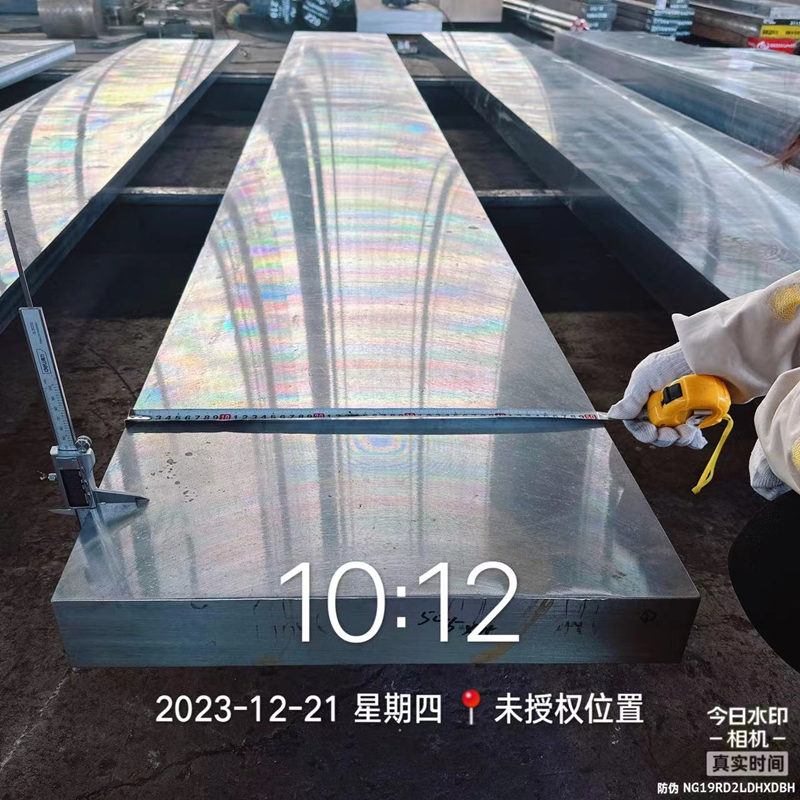

Size available:

Sheets or coils | Cold rolled | 0.5-2.5x100-1800mm |

Hot rolled | 3.0-16x100-1800mm |